Data cables come in various types, which can be confusing for users. Let’s explore the basic information about data cables and the types offered by ntsecurityusa in this article!

Introduction to Data Cables

Data cables are physical mediums used to transmit data and supply power between electronic devices. They act as a bridge, enabling communication and power transfer between devices that may have incompatible ports or functions. Data cables are designed with specific connectors at each end to ensure safe and efficient data transmission.

In industrial settings, cables play a crucial role in ensuring fast and efficient communication and data automation. This infrastructure is used to manage business technology needs, from computer networks and wireless Internet to video/audio cables, fiber optic installations, and data center setups.

Common Types of Data Cables Today

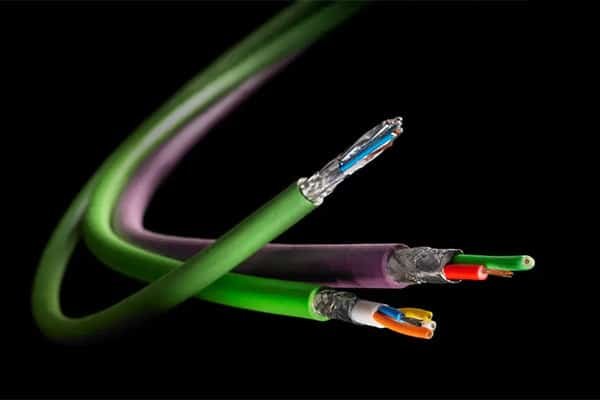

All types of wires and cables that contribute to communication in any way are generally referred to as data cables. However, there are significant differences, such as the entirely different structures of copper and fiber optic cables.

Copper cables come in various types, including low-frequency cables, coaxial cables, telephone cables, bus cables, diverse Ethernet systems, or microwave cables for specialized applications requiring transmission within the Gigahertz range. Selecting the wrong cable can quickly lead to costly disruptions and errors.

Generally, data cables are low-capacity cables, meaning that the less electrical energy accumulates in the cable during data transmission, the better. This electrical energy negatively affects signal quality, and the cable’s capacity partially depends on the insulating material.

Modern bus and Ethernet cables primarily use materials like PE or PP, which have excellent insulating properties, determined by measuring the dielectric constant (εr). The lower this value, the better the material’s insulating capacity, and the lower the cable’s capacity. This is why thinner insulation can be used with the same dielectric strength.

The structure of the cable plays a crucial role in data transmission. A solid, perfectly round wire with a uniform diameter provides the best electrical performance. For Ethernet cables and industrial bus cables, prioritizing AWG construction is important because this flexible design creates a round conductor.

Cables measured in metric systems are not suitable for this application because they have bundled structures and are not round. This results in varying capacity, significantly affecting high-frequency data transmission.

===> Learn more: The Functions Of An Automated Home

Common Mistakes in Choosing Ethernet and Bus Data Cables

Using Low-Frequency Data Cables for High-Frequency Applications

Using low-frequency data cables for high-frequency Ethernet connections is a common cause of data transmission issues. These cables have low capacity, but their impedance characteristics do not meet Ethernet standards, leading to incompatibility or connection disruptions.

In low-frequency data cables, all wire pairs are laid parallel, resulting in four identical lay lengths. In contrast, Ethernet cables used for high frequencies need to be optimally separated by using four different lay lengths, each measured individually. The position of the twisted pairs in the overall structure must also be carefully considered.

Classic Twisted Pair Coupling Instead of Star Quad

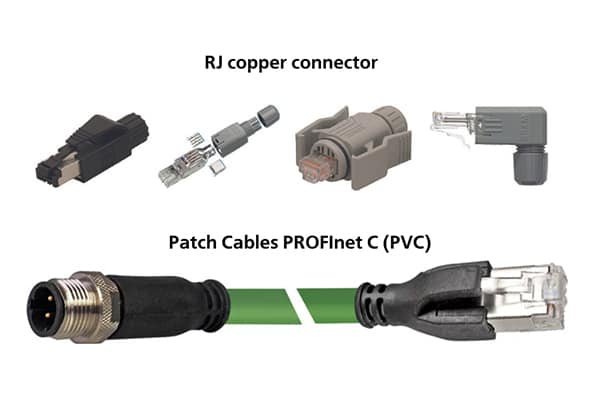

Many industrial communication standards like PROFInet, EtherCAT, or SERCOS III use data cables with two twisted pairs that are twisted into a star quad shape to transmit data. This method ensures all four cores are perfectly twisted round.

The benefit of this approach is that it does not cause differences in transmission time. This differs from classic twisted pair coupling, where twisted pairs must have two different twist lengths to ensure separation. Using the wrong type of twisted pair cable can lead to transmission timing and data latency issues.

In the star quad structure, the diagonal cores form an electrical pair. If this rule is ignored when connecting the cable, the cable’s characteristic impedance and near-end crosstalk (NEXT) will change, leading to degraded transmission quality. Even four-core shielded sensor cables are not suitable for use as bus cables or high-frequency industrial Ethernet cables, despite their seemingly similar structure.

The difference lies in the insulating strength of the core, which is not suitable for Ethernet, and the cable does not have a perfectly round structure, leading to inefficient operation due to non-compliant impedance, NEXT, and attenuation levels.

Data Cables That Are Too Long or Have Too Small a Diameter

Another common mistake is using excessively long segments. According to Ethernet standards, a repeater must be used after a maximum distance of 100 meters. This restores the signal strength before retransmitting it at full intensity.

In practice, longer segments exceeding 100 meters can be found, but they do not comply with current standards. In these cases, factors like temperature increase, aging, and other elements can quickly lead to defects or failures.

Thinner cables with an AWG 26 diameter are limited to distances of 60–70 meters. It is important to remember that each plug connector is a joint that causes signal loss due to attenuation and reflection, reducing the cable’s effective range.

The above information provides detailed insights into data cables. If you have any questions or are interested in installing cables for your business, please leave your information so that ntsecurityusa.net can provide consultation and installation services promptly!